Mastering Well Completions in 2024: Guide for Success

Posted: November 16, 2023

At the heart of thriving well production lies a critical cornerstone — the efficiency of a well completion. The U.S. Energy Information Administration (EIA) predicted that increased well productivity and higher oil prices will continue through 2024. Successful Operators are driving the need for safer, faster, and more efficient well production processes that mitigate costs while keeping up with current global demand. In turn, service providers are answering with better newer technologies to reduce installation times and trim nonproductive time (NPT) to lower CAPEX and OPEX, reducing the total cost per barrel.

Well completion plays a critical role at the onset of this process to extend the lifecycle of a well’s performance. Advanced techniques and strategic equipment selection can significantly improve the profitability of a well by maximizing production rates and reducing downtime. In this guide, we take a comprehensive look into mastering well completions in 2024. From challenges and technology advancements to flow control infrastructure, we explore how operators can optimize reservoir management and achieve economic success in the evolving oil and gas landscape.

The State of Well Completions in 2023

As we near the end of 2023, the present state of well completions is characterized by an increase in demand for drilling. This increased demand indicates a positive outlook for the well completion sector, with opportunities for growth and expansion. However, it also brings about certain challenges, including environmental concerns, regulatory changes, and competition within the industry.

The Present: Global Demand for Drilling to Increase

Global upstream investments in exploration, extraction, and production of oil and gas are up 11% from 2022 and are on course to reach $528 billion in 2023. That is the highest since 2015.

What’s more, Oil 2023, the International Energy Agency’s (IEA) medium-term outlook report, forecasts a 6% increase in global oil demand through 2028. The IEA bases this estimate on current government policies and market trends. The demand is driven largely by the petrochemical and aviation sectors.

As oil reserves become increasingly challenging to access, mastering well completions is crucial to maximize hydrocarbon extraction. By employing advanced technologies, techniques, and innovative flow control products, operators can gain a remarkable competitive edge.

Key Technological Advancements in Well Completions

Advances in well drilling and completion technologies play a vital role in meeting global energy demands. Specifically, they enable:

- The discovery of new resources

- Safer access to harsh or remote locations

- Making the development of challenged reservoirs economically viable.

These advancements also allow more oil and gas production with fewer wells. Consider these applications in well completions:

Horizontal Drilling

In horizontal drilling, the wellbore is initially drilled vertically to a certain depth. Then, the drilling process deviates to drill horizontally through a targeted reservoir zone that runs parallel to the reservoir formation.

The horizontal section of the wellbore intersects more of the reservoir’s pay zone— trapped oil or gas—than a vertical well. As such, horizontal drilling allows for increased contact with the reservoir, which can enhance production rates and recovery factors.

Horizontal wells are particularly beneficial in the following conventional and unconventional reservoirs:

- Thin-layered and heterogeneous conventional reservoirs

- Conventional reservoirs with natural vertical fractures

- Conventional reservoirs where water (and gas) coning will develop

- Unconventional shale gas and oil reservoirs

- Tight gas and/or oil reservoirs

- Unconventional coal bed methane (CBM), heavy oil, and oil sands reservoirs

Multilateral Drilling

A multilateral well is a type of wellbore configuration that consists of a main borehole with one or more additional wellbore branches radiating out from it. This single well with multiple lateral branches lets producers access and exploit hydrocarbon reserves at different depths or in different zones of a reservoir. Each lateral branch allows for drilling in different directions which increases contact with the reservoir and improves production efficiency.

Multilateral wells are used in various scenarios, such as exploration wells, infill development wells, or re-entries into existing wells. A successful multilateral well reduces overall drilling and completion costs by replacing several vertical wellbores and providing more efficient drainage. And because multilateral wells can access additional zones not reachable with traditional vertical wells, they can recover more hydrocarbons.

Extended Reach Drilling

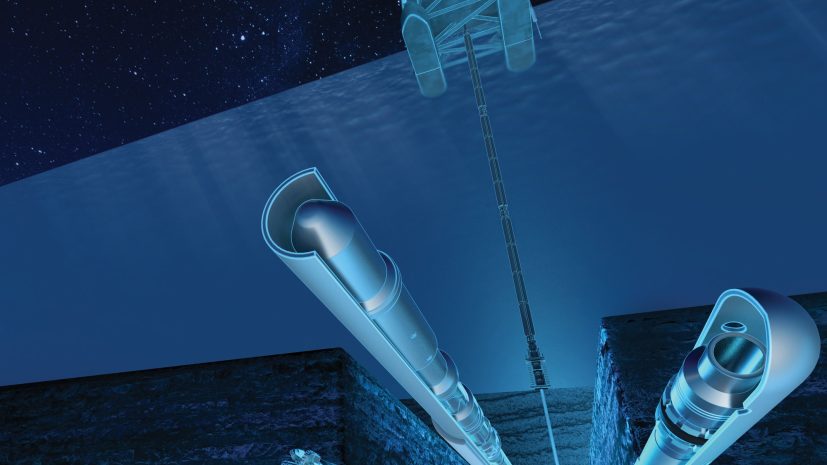

Extended reach drilling lets producers access deposits far away from the drilling rig. This enables them to extract oil and gas from areas where vertical wells are not feasible. These wells are expensive and technically demanding, but they can significantly lower costs by reducing the need for subsea equipment, pipelines, and fewer offshore platforms.

Combining extended reach drilling and advanced stimulation technologies allows oil companies to optimize fluid interaction with rock. This boosts production rates throughout the wellbore. In fact, companies have increased completion lengths from thirty to over 3,000 meters in recent decades. These advancements in drilling and well completions have also increased production from unconventional oil and gas reservoirs such as shale.

Additional Ways to Optimize Well Completions

In addition to the above drilling and completion structural innovations, the following advancements are furthering well completion optimization for efficiency, profitability, and safety:

- Intelligent Well Systems: Intelligent well systems use advanced sensors, downhole monitoring equipment, and real-time data analysis to optimize production. These systems provide valuable information on reservoir behavior, flow rates, and downhole conditions. Smart well insights enable operators to make informed decisions and optimize production performance.

- Sand Control Technologies: Sand control technologies prevent sand and other solids from entering the wellbore during production. Methods such as gravel packing, screens and filters, and chemical treatments help maintain well integrity, preventing damage to downhole equipment.

- Expandable Tubular Technology: Expandable tubulars expand and conform to the wellbore shape after installation into the hole. This eliminates the need for casing connections. The technology reduces drilling time and costs, improves well integrity, and enhances wellbore stability.

Looking Ahead: The Future of Well Completions in 2024

The EIA predicts that the production of crude oil will continue to increase to new records into 2024 with 12.8 million b/d, surpassing the previous record of 12.3 million b/d set in 2019. The Permian will increase by 350,000 barrels per day and in other U.S. regions by 70,000 barrels per day.

A decline is expected in oil use for transport fuels in the coming years and markedly slowed demand growth in China from 2024 onward. Despite this, petrochemical demand and consumption growth in developing economies will offset any downtick.

Although the outlook for 2024 is optimistic, the oil and gas industry continues to face significant challenges in its pursuit of exploration, production, and distribution of resources. These challenges arise from a range of factors, including shifting market dynamics, environmental concerns, technological advancements, and safety risks. Understanding and navigating these challenges is essential for the industry’s sustainability and resilience in an ever-evolving landscape.

Challenges Faced by the Oil and Gas Industry

The oil and gas industry has had three turbulent years, given the COVID-19 pandemic and Russia’s invasion of Ukraine. Markets are gradually recalibrating, but the energy sector still faces obstacles—particularly in terms of well completions.

1. Declining Reserves

As easily accessible oil and gas reserves become depleted, companies are increasingly turning to unconventional and hard-to-reach resources, such as shale formations and deepwater reserves. Extracting hydrocarbons from these harsh environments is both technically challenging and costly.

2. Environmental Impacts and Concerns

The oil and gas industry faces ongoing scrutiny and pressure to mitigate its environmental impact. Concerns include air and water pollution from drilling operations, greenhouse gas emissions, and the potential for oil spills and leaks. Meeting stringent environmental regulations and developing sustainable practices is important to the industry’s future.

Mastering well completions with effective wellbore integrity management and advanced well designs can reduce the likelihood of wellbore leakage and the contamination of groundwater resources. Current tolerant systems that can deploy and recover quickly allow customers the ability to operate in narrow weather windows between hurricane seasons, loop currents, and other weather events minimizing (NPT) delays supporting sustainability programs.

3. Cost and Price Volatility

The oil and gas industry is sensitive to fluctuations in commodity prices which can impact investment decisions and profitability. Operators and service providers must continually manage the costs associated with exploration, drilling, production, and infrastructure development while navigating market dynamics.

4. Safety and Accidents

Drilling and production operations are inherently hazardous. Accidents such as blowouts, well control issues, or equipment failures can lead to injuries, environmental damage, and reputational harm. Implementing robust safety protocols and maintaining a strong safety culture are necessary to minimize risks.

5. Technological Complexity

Extracting oil and gas from unconventional reservoirs requires newer technologies and techniques that are more efficient. Implementing and keeping up with rapidly evolving technologies can be costly and challenging.

Addressing these challenges requires investment in research and development, adoption of sustainable practices, regulatory compliance, infrastructure reliability, and priority to safety in order to stay ahead of the competition.

Mitigating Challenges: Considerations for Efficient Well Completions

Global regulatory agencies are leading the push toward safe drilling and high operating standards. As a result, both off- and onshore operators are starting to link performance objectives to reliable equipment performance.

When selecting well completion equipment and materials, it is critical that operators also consider design versatility. System integration testing (SIT) between systems and subsystems (for example downhole completion tools, completion landing strings, surface well test layouts are key systems). Using common components across systems allows for a streamlined spare strategy in which component versatility will serve a variety of fields and conditions.

As a leader in essential flow control products, Gilmore partners with industry experts to develop products that ensure our clients in well completions can optimize well efficiency and uptime. Gilmore helps address critical industry challenges and improve well completion efficiency by leveraging modern technologies, improving component quality, and reducing operation costs. Partnering with industry experts continues to drive innovative product designs for all the markets we serve.

1. Technology

Data analytics and machine learning are playing key roles in optimizing well completions. By leveraging large datasets and advanced algorithm technologies to help engineers and operators make more informed decisions to improve efficiency and maximize production.

Gilmore continues to build on its energy heritage and experience, through the development of adaptable and modular technologies that go beyond standard applications, pushing the envelope of valve reliability. Control valve designs employ soft-sealing and shear-sealing technologies utilizing specialty materials and Tungsten Carbide to achieve industry-leading seal reliability and durability, even in the harshest conditions.

2. Exceptional Quality

Well completion component durability is a principal factor to maintaining equipment productivity and output. By prioritizing longevity in all our product designs, Gilmore assists operators and service providers in optimizing essential infrastructure with reliable flow control solutions that significantly reduce repairs, change-outs, materials, and labor requirements.

Gilmore’s flow control solutions are debris-tolerant and corrosion-resistant. Products stabilize quickly to achieve a constant state of flow rate and well pressure. Product Engineers designate component material selection and design improvements supported with field and lab performance data to ensure peak performance. The result is reliable flow control solutions that provide end users with predictable maintenance schedules for maximized uptime.

3. Costs

Contaminated and solids-laden fluids are one of the industry’s most frequent causes of downtime and inefficiency. Gilmore’s GEN2 and Mark IV product solutions for interventions, completions, plug and abandonment systems are debris tolerant and employ soft-sealing and shear-sealing technologies utilizing specialty materials and Tungsten Carbide to achieve industry-leading seal reliability and durability. Products are designed to be used in both topside and subsea applications with high pressure and flow capacities.

Gilmore’s new Agiliti™ product solutions for well stimulations pressure control systems utilize the same technologies applied to the critical service subsea products to extend performance, life, and the economics of frac fleets in the unconventional market. Gilmore knows achieving more stages per day, safely and efficiently, with less NPT, drives business value.

In addition to available flow control product solutions, Gilmore has the agility to tailor reliable solutions to meet client specifications for both in-service systems and those under development. Every operator and service provider can benefit from improved efficiency.

A Trusted Partner for Successful Well Completions

Well completions in the year ahead will continue to improve with innovative technologies. Oil companies and operators must embrace operational, technological, and drilling advancements to remain competitive in 2024.

Innovative technologies will help oil and gas companies mitigate price volatility, improve efficiency, and output, and achieve decarbonization—a significant factor in securing investments and remaining compliant.

With 60 years of experience and a focus on developing advanced, innovative, and customizable technologies, Gilmore offers reliable flow control solutions even in the harshest of environments. Our team of engineers consistently prioritizes efficiency, safety, and reliability in its designs. This means that you have fewer maintenance cycles and profit from extended periods of operation.

Connect with us today to learn how our solutions can help reduce operational costs, boost productivity, and ensure safety and reliability for your energy operations.